Below we give you an overview of our production facilities.

Due to the plant expansion in recent years, it has been possible to expand the machinery in operation to the present state. Furthermore, we have a well-equipped metalworking department with optimized workplaces.

Machinery in operation

CNC – Boring machine:

Rapid 1 NC 2.200mm x 1.300mm x 630mm

CNC – Milling machines:

Soraluce SORA 4 4.000mm x 1.000mm x 1.600mm

WHN 10NC 1.250mm x 1.250mm x 600mm

Maho MH1000 1.000mm x 560mm x 800mm

DECKEL FP-5A 600mm x 400mm x 400mm

CNC – Turning lathe/Carousel-type machine:

SARO – WEMATECH – Ø1000mm x 2000mm

Karussell MAZAK – Ø1450mm

Turning lathes:

Potisje Ø600mm x 3.000mm

Potisje Ø600mm x 1.500mm

Manipulation:

Abus overhead crane 10m x 20to

Abus overhead crane 10m x 10to

Vulkan overhead crane 10m x 5to

Jungheinrich fork lift 4,5to

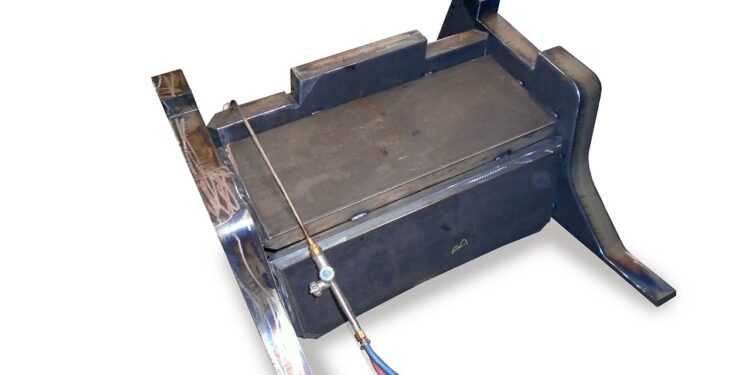

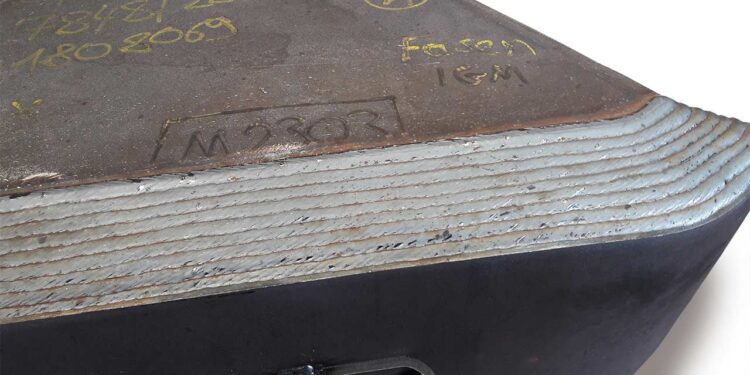

Welding procedures:

All established methods (MIG, MAG, WIG, Autogen)

Sand blast chamber:

4m x 4m x 8m

Cooperation treaties

For all areas of production which cannot be directly covered by our company a broad range of close-by co-operation partners are at our disposal (e.g. boring machine of larger dimensions, welded constructions, heat treatments like low stress annealing, nitriding, quenching and tempering, etc.).